Advanced Energy exhibited at the recent Pittcon Conference and EXPO that took place on Mar 20-22 at the Pennsylvania Convention Center, PA. With approximately 450 exhibitors and 15,000 attendees, Pittcon is the premier event to discover the latest solutions for life science and analytical equipment. In addition, the over 1,000 technical sessions highlighted the latest trends in the industry.

Pittcon 2023 was a return to an in-person event after two years. As some in the industry may remember, Pittcon 2020 was cut short due to concerns over the COVID-19 virus that was rapidly spreading through the U.S. In its first year back as an in-person event after the pandemic, we observe that COVID-19 continues to be a driving force behind some of the latest trends in the life science industry.

Here are some of the key trends we observed at the show:

Faster Testing and Analysis

The COVID-19 pandemic highlighted the need to conduct testing faster while maintaining the integrity of the results. Greater access to testing and rapid results improve patient outcomes and significantly help limit infection. This is driving companies to develop systems with higher throughput capability, increased laboratory automation and faster analysis methodologies.

Faster Time-to-Market

A study from the U.S. National Institutes of Health (NIH) Nature Public Health Emergency Collection finds that the risk of future pandemics has increased significantly in recent years due to human impact on the environment – from climate change and habitat degradation to destruction of biodiversity and animal trade.

RNA viruses are one of the most prevalent types of viral agents. With high mutation rates, they evolve and adapt to their environments rapidly, underlying the need for humans to react quickly to address their spread. The emergence of mRNA vaccine technology has aided the fight against these diseases. Life science companies face the challenge of bringing both the mRNA vaccines and the testing equipment to market quickly.

Now, it’s more important than ever to engage with strategic partners and collaborate early in the design and development process to bring products to market more quickly. Advanced Energy’s Customer Experience Centers (CEC) work with customers around the world to solve design challenges throughout their product lifecycle. Our Sharon, MA center services our life science customers with an experienced engineering team as well as sophisticated EMI, thermal and electronic test equipment.

Digital Transformations

Similar to many other industries, the pandemic has driven life science companies to dramatically alter how their businesses run, as well as how R&D can continue at pace. Digital transformations permeate many aspects of the industry.

There is an increased use of cloud technologies to enable employees to work remotely while fostering collaboration. Additionally, we see increasing adoption of Artificial Intelligence (AI) and Machine Learning (ML) algorithms to collect data, generate insights and accelerate analysis in a wide variety of applications ranging from drug discovery to personalized medicine.

In drug discovery, AI and ML can be used to analyze large datasets and predict which drug candidates are most likely to be effective, reducing the time and cost of bringing new drugs to market. AI and ML can also be used to identify potential side effects and drug interactions, improving the safety and efficacy of new drugs.

In personalized medicine, AI and ML can be used to analyze patient data and identify individualized treatment options based on a patient's unique genetic makeup and medical history. Next-generation cell therapies, including gene editing, enable personalized treatment, which can yield improved patient outcomes compared to mass-produced medicine.

Personalized Medicine: Cell Therapy Enters the Mainstream

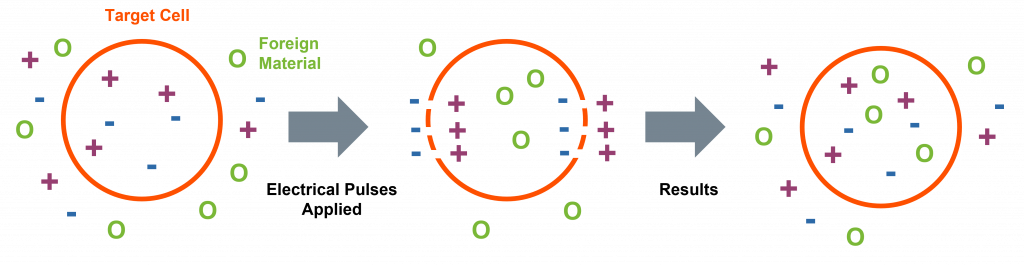

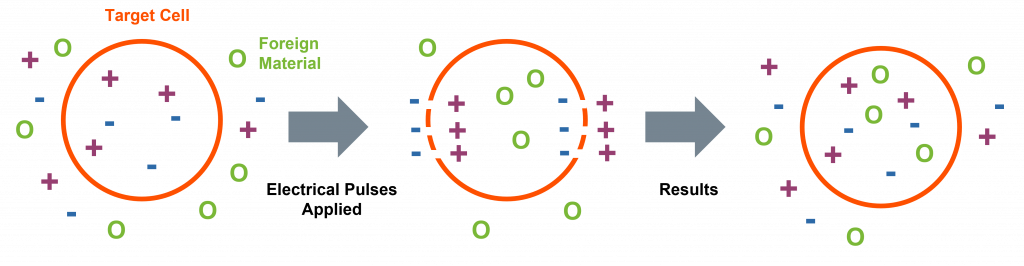

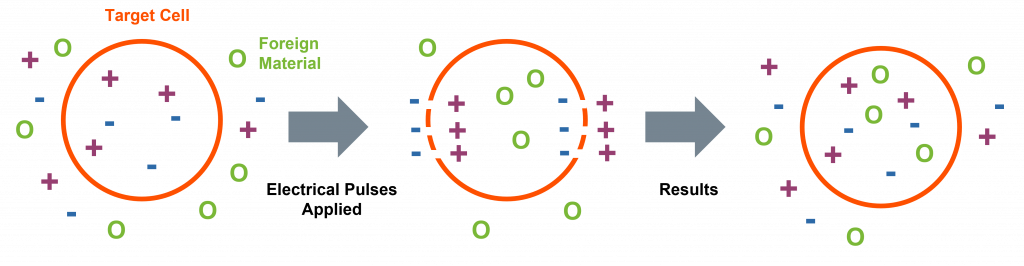

Expanding upon the increased use of personalized medicine, the success of cell therapy in treating various diseases and conditions has contributed to its growing popularity. Cell therapy involves the injection of foreign material into a patient's cell to change the cell’s properties, tailoring treatment to alleviate symptoms and cure diseases.

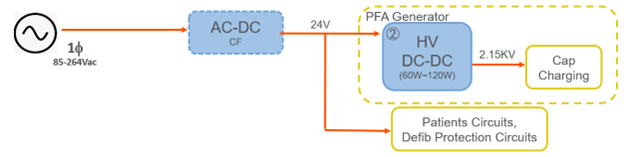

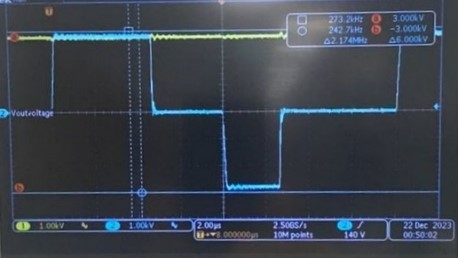

These therapies, also known as transfection/electroporation, require precise high voltage power delivery and control. Electroporation works by suspending the target cells and the foreign materials being introduced into the cells in an electrically conductive solution. Very short and highly controlled electrical pulses are applied via electrodes to induce a reversible breakdown of the cell membrane and the opening of pores that allow the foreign molecules to enter. Ultra-miniature, programmable high voltage precision DC-DC converters such as Advanced Energy’s UltraVolt© AEQ series and the high power UltraVolt C series deliver the stability and repeatability required to ensure reliable equipment operation over many years.

These therapies, also known as transfection/electroporation, require precise high voltage power delivery and control. Electroporation works by suspending the target cells and the foreign materials being introduced into the cells in an electrically conductive solution. Very short and highly controlled electrical pulses are applied via electrodes to induce a reversible breakdown of the cell membrane and the opening of pores that allow the foreign molecules to enter. Ultra-miniature, programmable high voltage precision DC-DC converters such as Advanced Energy’s UltraVolt© AEQ series and the high power UltraVolt C series deliver the stability and repeatability required to ensure reliable equipment operation over many years.

Miniaturization of Point-of-Care Treatment

Learnings from the COVID-19 pandemic have also accelerated the trend towards portable equipment in the life sciences industry. The need for flexibility, rapid testing and field research has increased the demand for portable technologies.

Companies are focusing on smaller, more portable devices that can be used at smaller clinics with greater proximity to the patient, in ambulatory environments, and even at home. This will have a significant impact on equipment design from a size perspective – the challenge is to reduce size while making sure testing outcomes are not compromised.

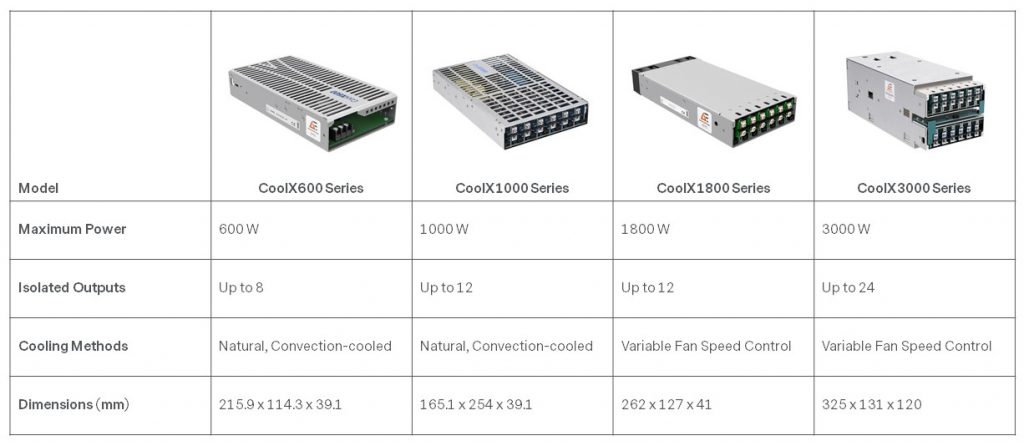

This trend is driving the use of power supplies with higher power densities, such as Advanced Energy’s CoolX series and UltraVolt high voltage solutions. Equipment makers are also designing systems that can support multiple functionalities, enabling a wider variety of tests using the same equipment.

Conclusion

The COVID-19 pandemic has driven significant changes in the life science industry, with many trends focused on digitalization, speed, efficiency and portability. In this dynamic environment, collaborating early in the design process and engaging strategic partners is crucial to bringing products to market quickly.

These therapies, also known as transfection/electroporation, require precise high voltage power delivery and control. Electroporation works by suspending the target cells and the foreign materials being introduced into the cells in an electrically conductive solution. Very short and highly controlled electrical pulses are applied via electrodes to induce a reversible breakdown of the cell membrane and the opening of pores that allow the foreign molecules to enter. Ultra-miniature, programmable high voltage precision DC-DC converters such as Advanced Energy’s

These therapies, also known as transfection/electroporation, require precise high voltage power delivery and control. Electroporation works by suspending the target cells and the foreign materials being introduced into the cells in an electrically conductive solution. Very short and highly controlled electrical pulses are applied via electrodes to induce a reversible breakdown of the cell membrane and the opening of pores that allow the foreign molecules to enter. Ultra-miniature, programmable high voltage precision DC-DC converters such as Advanced Energy’s