Artesyn.com, SLPower.com, and TEGAM.com are now part of AdvancedEnergy.com. Learn more

Precision. Power. Performance. Trust.

Cutting-Edge Products from the Innovation Powerhouse

New & Featured Applications

Explore All ApplicationsFeatured Videos

View AllClose Popup

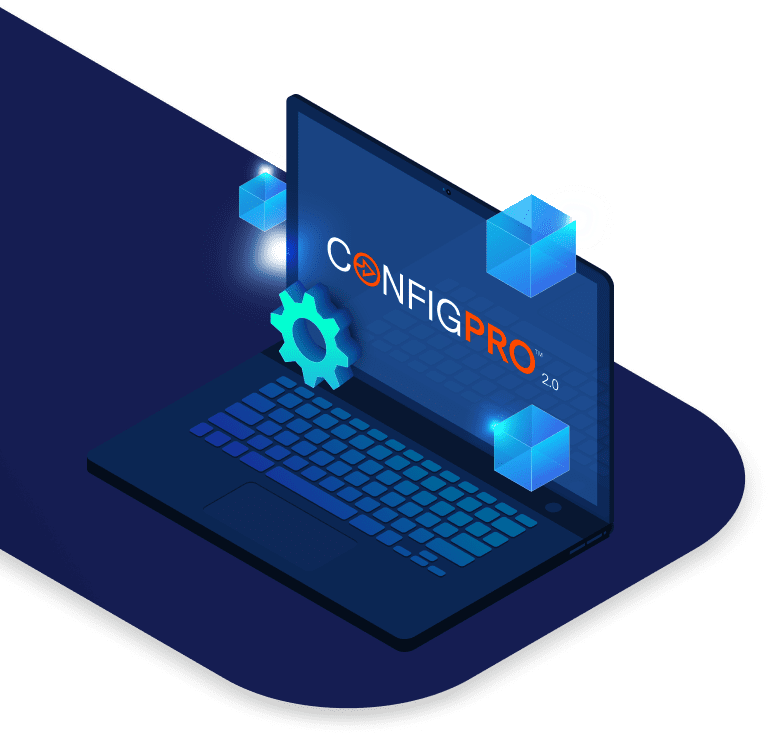

Introducing ConfigPro

Advanced Energy’s Revolutionary Online Power Configurator

With over 3 million configurable power supply combinations, this power solution algorithm optimizes cost and guides you to the ideal solution for MP, IMP, IVS, and MICROMP (UMP) configurable power supply families.

Get Started

.jpg?lang=en-us)

.jpg?lang=en-us)

.png?resizemode=force&maxsidesize=408)